EATON - Electronic Motor Starter

With its EMS electronic motor starter, Eaton is setting a new standard by offering a multifunctional motor protection and control relay with a frame width of 30 mm. This electronic motor starter is intended for applications in which motors with a performance range from 0.06 kW to 3 kW need to be reliably driven and protected while using up as little space as possible.

Target applications

Logistics

Conveyor control

Production machines

Tooling machines

Packaging machines

Small elevators

Agriculture automation

Advantages for Conveyor

SIL-3 E-Stop contacts

E-Stop is required by Standard 1926.555 of the United States Department of Labor

Direct and reversing motor starter

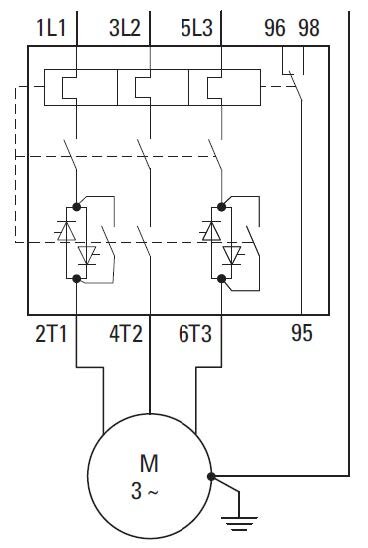

Hybrid contact technology

High life span (30 Million switching cycles)

Avoids process / machine interruptions

Avoids device replacements

EMS interrupts the motor on all phases

No voltage on the output terminals in OFF (unlike semiconductor relays)

OFF

Contactor Isolation

Switching On

No make load on contacts

ON

No heat on SSRs

Switch OFF

No break load on contacts

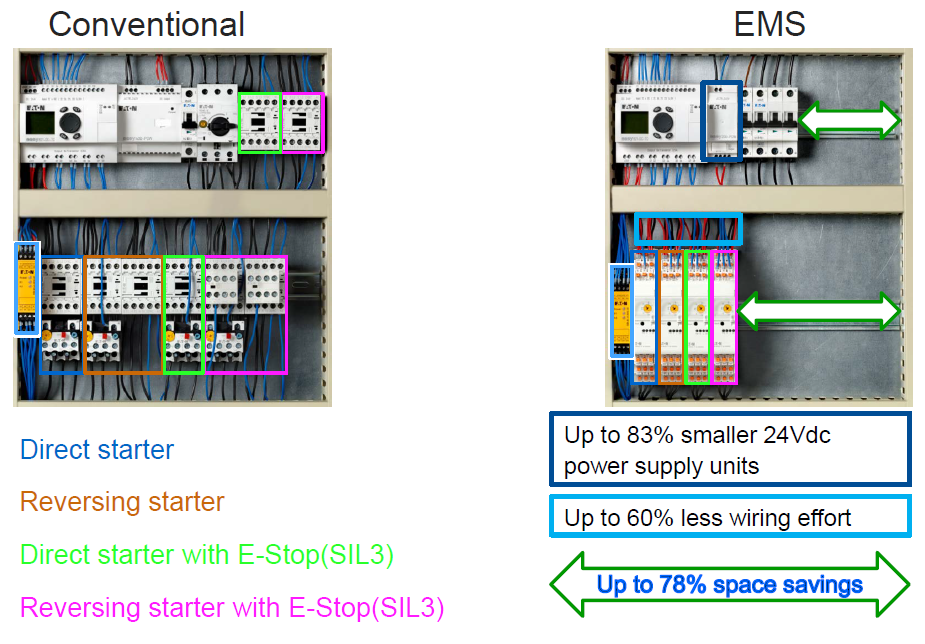

Comparison to Standard Motor Control Combinations

Conventional wiring

Time intensive and error-prone wiring

Limited information about the process

Additional I/O level for controlling and monitoring devices

SmartWire-DT solution

Faster commissioning due to pluggable control wiring

Space saving via substitution of digital PLC I/Os

More information about the process and making it more stabile

Eaton’s SmartWire-DT is an intelligent machine wiring solution that reduces panel and machine wiring complexity by consolidating complex circuit wiring into a single cable. When assembling your machine, connecting components over SmartWire-DT is fast and simple both inside and outside the control cabinet. Once the machine is built, SmartWire-DT streamlines testing and reduces installation, commissioning and troubleshooting to save you time and money.

Specifications

AC-51 - non/slightly inductive loads (power factor > 0,95)

AC-53 - motor loads with high inrush (about 5-7 times of FLA),control of a squirrel-cage motor

Functions

Motor direct start

Motor reversing start

Motor protection

E-Stop with Cat. 3 / SIL3 / Ple

Communication interface SWD

HP ratings

0.5 – 5 HP @ 480V

Current range

0.18…9.0A

0.18A…2.4A

1.5A…6.5A/7A (SWD)(AC-53a) 9.0A (AC-51)

Control voltage

24Vdc (SWD self supplied)

Device width

30mm

Certifications

CE, cULus, ATEX, CCC, EAC